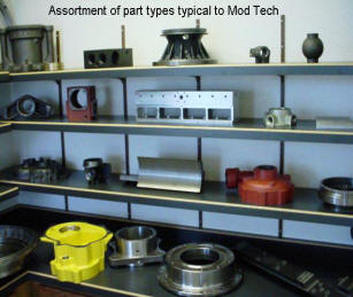

Equipment and Facilities

Turning Centers

Twin spindles both vertical and horizontal for maximum production and lowest possible part cost.

From 1" diameter to large 27" diameter capacities.

Twin spindles both vertical and horizontal for maximum production and lowest possible part cost.

From 1" diameter to large 27" diameter capacities.

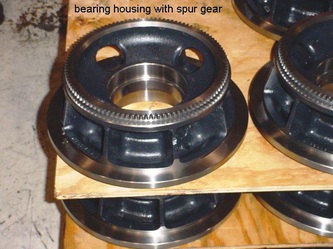

Grinding, Gear Cutting

Lineal surface grinding 30"x72"

Spur gear shaping to 36"

Lineal surface grinding 30"x72"

Spur gear shaping to 36"

|

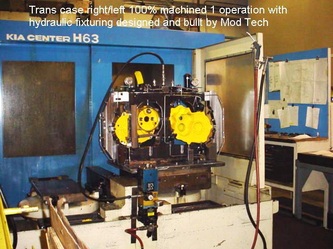

Tooling, Workholding

Mod Tech designs and builds specialty custom cutting tools for efficient productivity. Mod Tech designs and builds all work holding in house. The result is innovative, low cost short lead times work holding solutions. From sophisticated sequenced hydraulic fixtures, innovative tooling, Mod Tech can support your product needs. |

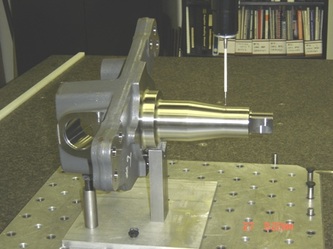

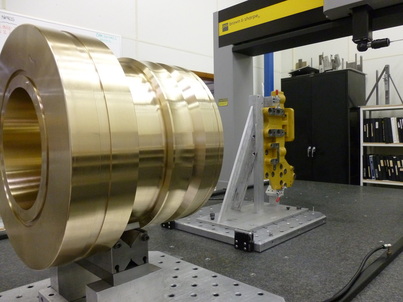

Quality

DCC CMM with scanning to provide absolute accuracies on complex parts. Large 47" x 78" x 39" work envelope.

Our CMM is equipped with a MTI designed air assist movement or AAMs system (patent pending) for increased efficiencies. This system is available for your CMM by contacting us at MTI. You can also see a demonstration on this website.